Welcome To

Profile Laser

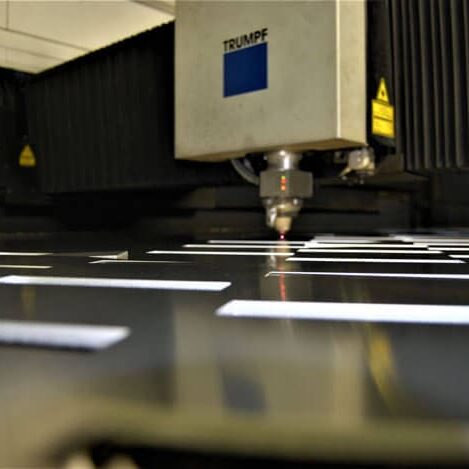

Founded in 2011, Profile Laser has created a team with extensive background in CAD, metal laser cutting and fabrication. Our diversity in CAD rendering, CNC programming, laser operations and post laser processing allows us to produce the best possible product for our customers. We specialize in precision laser metal cutting for industrial, commercial, and design applications.

What We Do

Our Services

You'll make a statement and stand out from the competition with our precision laser-cut metal products. We are able to offer a modern look to any project using our custom etching and engraving process. From impressive company signage to industrial parts for equipment, we produce high-quality results to your exact specifications.

In addition, we have used the same technique to produce high-grade grating screens for processing machinery and heavy machinery components. The possibilities are endless.